Fused Silica Windows

Fused silica windows provide unparalleled optical clarity and exceptional durability across a wide range of wavelengths from UV to infrared. They are perfect for environments where thermal stability and chemical resistance are essential.

Benefits of Fused Silica Windows

Broad Spectral Transmission

Effective from ultraviolet (UV) to infrared (IR), supporting diverse optical applications.

Thermal Stability

A low thermal expansion coefficient ensures performance under temperature fluctuations.

Chemical Resistance

Resists degradation from acids and other corrosive substances, maintaining integrity.

Durability

High mechanical strength and hardness protect against physical and environmental stress.

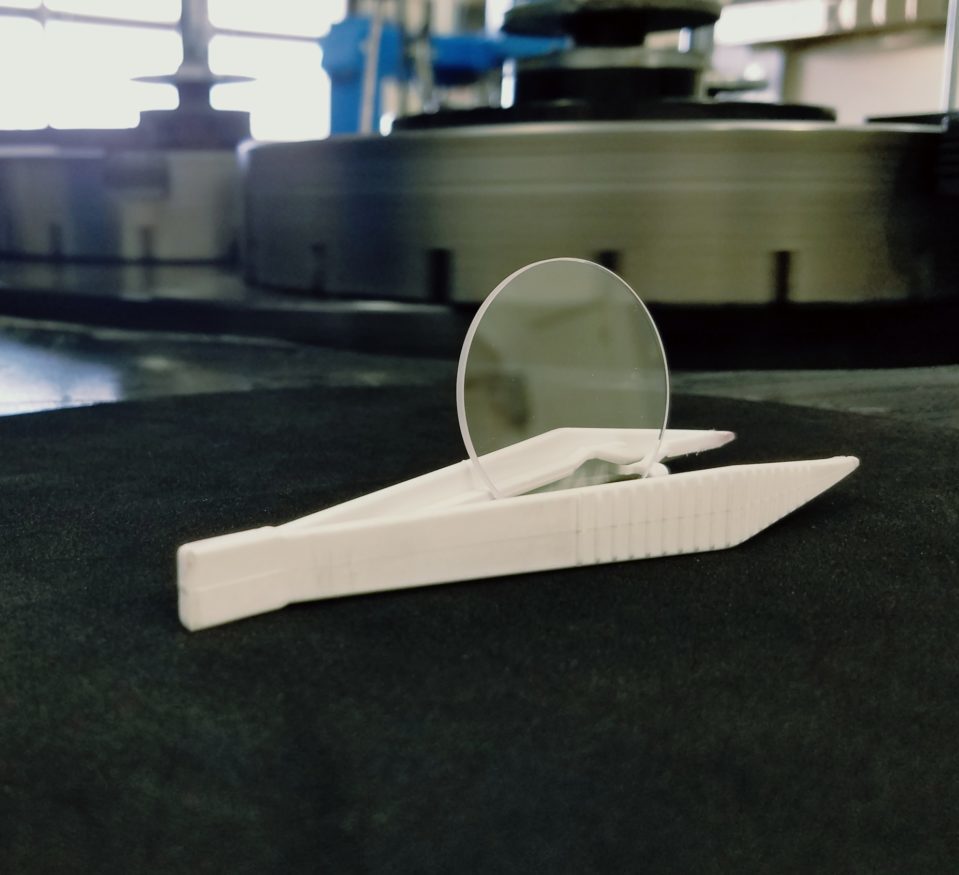

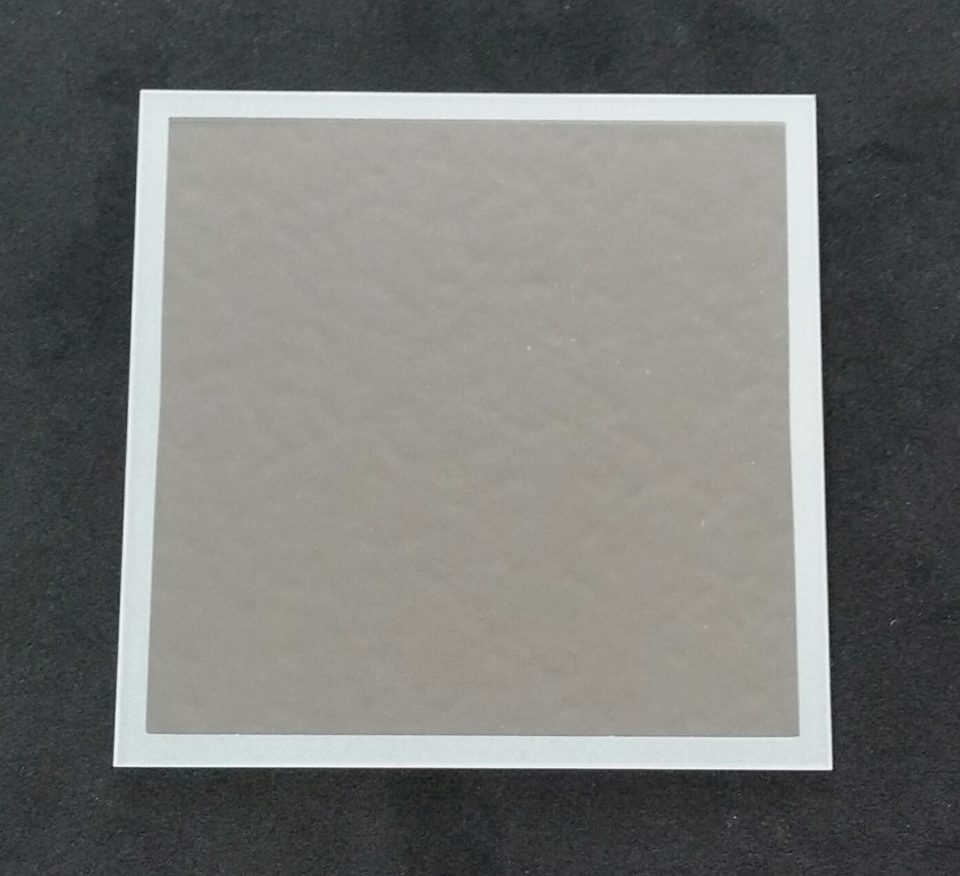

Fused Silica Window Examples

What are Fused Silica Windows?

Due to their exceptional optical properties and durability, fused silica windows are highly prized in technical and scientific applications. Made from synthetic amorphous silicon dioxide, these windows boast remarkable transparency across a wide spectral range, from ultraviolet (UV) to infrared (IR). They are particularly valued for their low thermal expansion coefficient, ensuring dimensional stability and thermal shock resistance under rapid temperature changes. Additionally, fused silica is chemically inert, making it resistant to most acids and other corrosive agents. This combination of features makes fused silica windows ideal for harsh environments where high optical clarity and physical reliability are paramount.

| Diameter: | From 1 mm (.039") to 228 mm (9") |

|---|---|

| Thickness: | Nearly any thickness; varies by diameter |

| Surface Quality: | Down to 40/20 Scratch/Dig |

| Quantities: | From singles to full production runs |

Frequently Asked Questions

What are the key properties of fused silica windows?

Known for their exceptional optical clarity and high transmission from UV to infrared wavelengths. They are highly resistant to thermal shock due to their low thermal expansion coefficient and are chemically inert, making them resistant to most acids and solvents.

Why are fused silica windows used in high-temperature applications?

Due to their low thermal expansion coefficient, fused silica windows can withstand extreme temperature changes without deforming or cracking. This makes them ideal for high-temperature applications, including aerospace, semiconductor manufacturing, and laboratory equipment.

Can fused silica windows be used in UV applications?

Yes, they are excellent for UV applications because they have high transmission rates in the ultraviolet spectrum. This makes them suitable for use in UV spectroscopy, UV lasers, and other applications requiring UV light transmission without degradation.

Start your Fused Silica Window project today

For a quote on your custom requirements please send us your drawing or specification.