Sapphire Windows

Sapphire windows provide unparalleled durability, wide spectral transparency, and resistance to extreme conditions, making them essential in high-performance applications across various industries, from aerospace to scientific research.

Benefits of Sapphire Optical Windows

Handles High Temperatures and Pressures

Sapphire windows are exceptionally tolerant to extreme temperature fluctuations and pressure differences, making them ideal for use as viewports in vacuum chambers or environments containing high-temperature plasma.

Wide Transmittance Range

Sapphire windows are transparent across a broad spectrum, from 170 nm to 5.5 µm, making them suitable for a wide array of optical applications.

Unique Sapphire Material Properties

Being a single crystal form of Al2O3, sapphire combines a set of advantageous chemical, mechanical, and optical properties. Learn About Sapphire Properties »

Chemical Resistance

Sapphire is resistant to strong acids, facilitating its use in corrosive atmospheres.

Scratch and Abrasion Resistance

With a high Knoop hardness of 1800 parallel to the optic axis and 2200 perpendicular, sapphire windows offer superior resistance to scratches and abrasion.

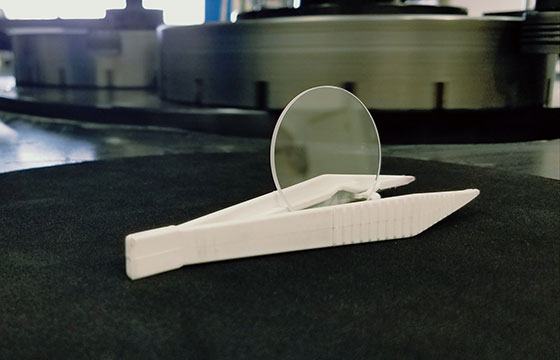

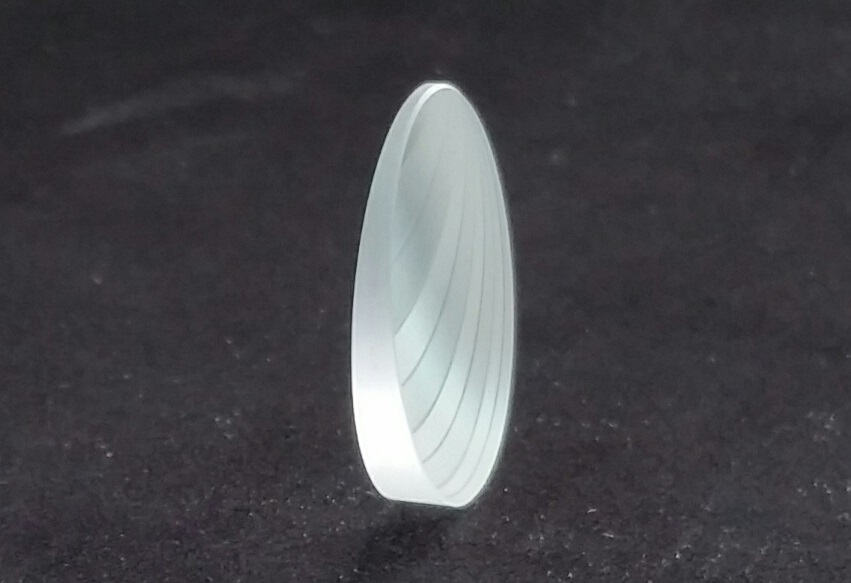

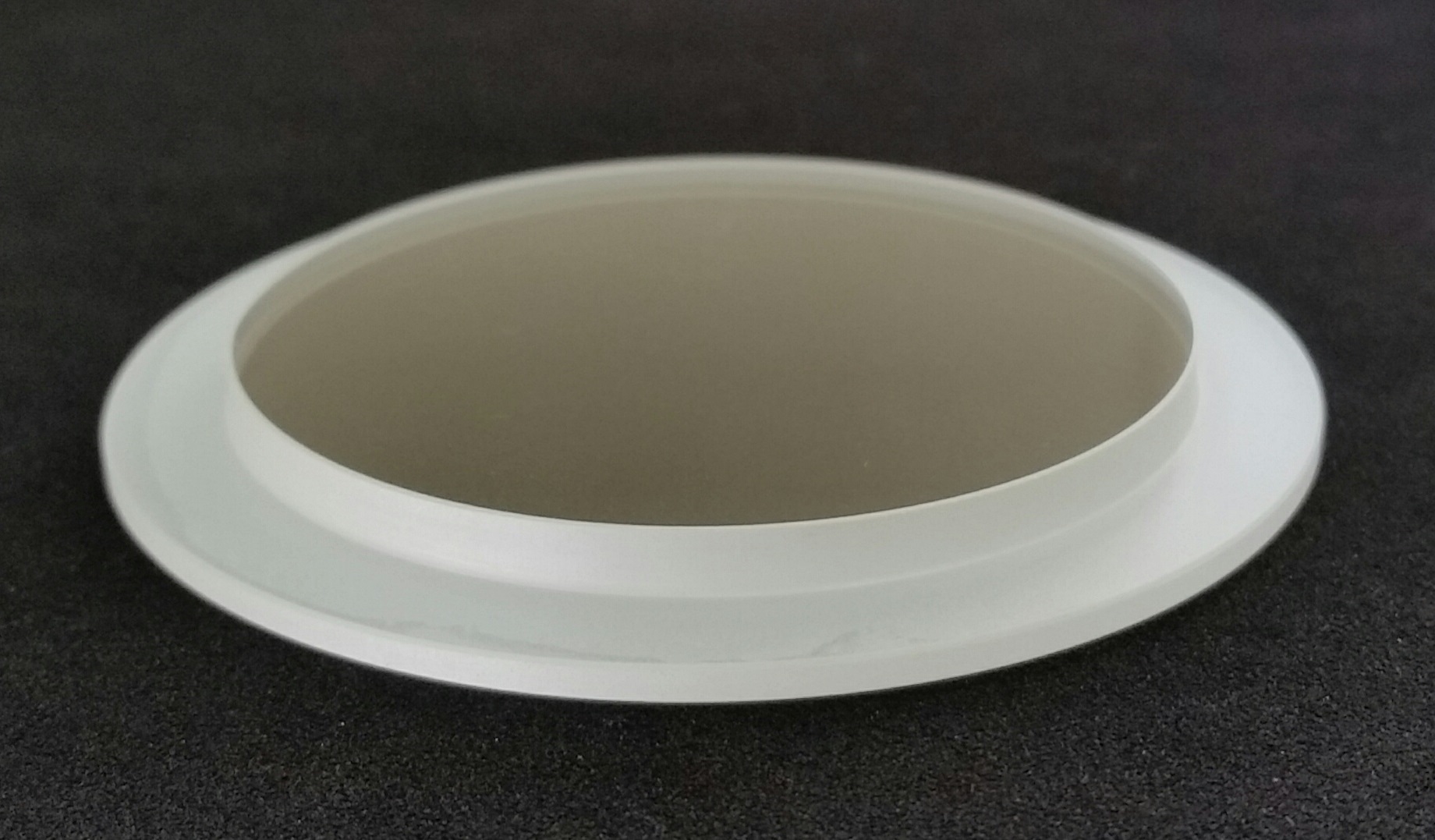

Sapphire Window Examples

Perfecting the art of fabricating the highest quality sapphire windows

Custom Sapphire Windows manufactured by Guild Optics are considered among the best in the industry. Our custom sapphire optical components are excellent at protecting delicate lasers, sensors, cameras, and other devices due to their superior strength and scratch resistance. Sapphire Optics can also be used as viewports in high-pressure or vacuum situations. Sapphire windows for pressurized enclosures can be made much thinner than their optical glass counterparts due to sapphire’s high modulus of rupture. With a MOHS hardness of 9, sapphire is second only to diamond, plus it transmits from 190nm to 5000nm, making it a great choice for UV applications and mid-wave infrared.

Click to see the Properties of Sapphire »

| Diameter: | From 1 mm (.039”) to 430mm (17”) in any optical axis |

|---|---|

| Thickness: | Varies by Diameter but can be sub millimeter and up |

| Flatness: | Varies by thickness but can be 1/10 wave or better if needed |

| Parallelism: | Varies by size but can be as tight as 1 arc second |

| Surface Quality: | Down to 10/5 Scratch/Dig |

| Quantities: | From singles to full large scale production runs |

| Alternate Materials: | Bk7, Fused Silica, Quartz, and Optical Glass |

Frequently Asked Questions

What is a sapphire window?

A sapphire window is a transparent component made from synthetic sapphire, a form of aluminum oxide crystal known for its exceptional hardness and durability. These windows are highly resistant to scratches, thermal stress, and chemical corrosion, making them ideal for use in environments that are too harsh for standard glass. Due to their superior physical and optical properties, sapphire windows are extensively used in scientific instruments, high-pressure vessels, aerospace applications, and electronic devices where clear, durable, and stable optical performance is crucial.

Why are sapphire windows better than glass optical windows?

Sapphire optical windows hold several advantages over traditional glass optical windows, particularly in their durability and performance under extreme conditions. Sapphire, a crystalline form of aluminum oxide, is exceptionally hard—ranking 9 on the Mohs scale, just below diamond. This extreme hardness makes sapphire windows highly resistant to scratching and abrasion, an essential quality in environments where particulate matter might scratch or degrade lesser materials.

Furthermore, sapphire windows boast superior thermal properties. They can withstand temperatures up to 2030 degrees Celsius without losing strength or shape, making them ideal for high-temperature applications that would deform or melt standard glass optics. Sapphire also exhibits excellent chemical resistance, able to withstand exposure to corrosive substances and strong acids without surface damage. This resistance ensures optical clarity and effectiveness remains intact even in chemically harsh environments.

In addition to mechanical and thermal robustness, sapphire windows provide superior optical clarity across a wide range of wavelengths, from ultraviolet to near-infrared. This makes them versatile for various optical applications where precise light transmission and clarity are required. While glass windows are sufficient for everyday applications, the demanding conditions of scientific, military, and industrial settings often necessitate the robust features of sapphire optical windows. These characteristics distinctly make sapphire a preferred choice where durability, clarity, and performance under stress are paramount.

Do sapphire windows cost more than glass windows?

Due to several factors, sapphire optical windows generally come at a higher cost than traditional glass optical windows. The primary reason is the material and manufacturing processes involved. Sapphire is a synthetically produced crystal that requires high temperatures and significant energy to produce, making the initial material more expensive. Additionally, machining sapphire into precise optical windows is a complex process; sapphire’s extreme hardness, while beneficial for durability and performance, also means that special equipment and techniques are required to shape and polish it. This adds to the production costs. In contrast, glass is easier and cheaper to manufacture and can be processed at much lower temperatures with less specialized equipment. Although sapphire windows are more expensive, they are justified for applications demanding high durability, thermal resistance, and optical clarity where the long-term benefits offset the initial investment.

Start your sapphire window project today

For a quote on your custom requirements please send us your drawing or specification.